Plant Description

Abu Qir power project is designed to include a 2×650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500 KV GIS switchyard.

The power block is comprised of two identical Rankine cycle turbine generator units, each with a nominal rated capacity of 650 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both. The two-unit station arrangement includes an enclosed turbine building, an open boiler building, a common control room, and all associated structures and facilities.

The project contracting plan utilized a multi-package system. Nineteen (19) contracting packages and purchase orders procured the equipment and services.

Plant Description

Cairo West power project is designed to include a 2×350 MW thermal power plant to interconnect with the National Unified Power System (NUPS) through a GIS 500 KV switchyard.

The power block is comprised of two identical Rankine cycle turbine generator units, each with a nominal rated capacity of 350 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both. The two-unit station arrangement includes an enclosed turbine building, an open boiler building, a common control room, and all associated structures and facilities.

The project contracting plan utilized a multi-package system. Sixteen (16) contracting packages and purchase orders procured the equipment and services

Plant Description

El Tebbin power project is designed to include a 2×350 MW thermal power plant to interconnect with the National Unified Power System (NUPS) through a GIS 220 KV switchyard. The power block is comprised of two identical Rankine cycle turbine generator units, each with a nominal rated capacity of 350 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both. The two-unit station arrangement includes an enclosed turbine building, an open boiler building, a common control room and all associated structures and facilities. The facility includes a water treatment plant that provides make-up water to the cycle. A 220 KV GIS switchyard evacuates the generated power to the national grid.

The project contracting plan utilized a multi-package system. Eighteen (18) contracting packages and purchase orders procured the equipment and services.

Plant Description

Ayoun Moussa 1&2 station consists of:

- Two indoor condensing steam turbine generator (STG) units, each capable of delivering 320 MW net power at the generator terminals.

- Two outdoor, dual firing, pressurized furnace steam generators.

- Auxiliary equipment including onsite oil storage, a natural gas pressure reducing and handling facility, a desalination plant for plant make-up water, an off-shore cooling water intake structure, a water and waste water treatment facility, a GIS 220 kV indoor switchyard, 220 kV transmission lines, and a housing colony.

Procurement activities for the project included the full scope of contract/purchase order formation and administration activities covering per-qualification and evaluation of bidders, issuance of bid documents, bid evaluation, contract negotiations, contracts awarding and expedition.

The project contracting plan used a multi-package system. Twelve (12) contracting packages and seven (7) purchase orders were awarded to different contractors and suppliers to provide the station goods and services. The plant Owner awarded the different packages while PGESCo acted as the Owner authorized representative. The plant was turned over to the Owner and is in stable commercial operation since 2001.

Plant Description

Sidi Krir 3&4 power project consists of two 340 MW steam turbine generator units and two outdoor dual fired, pressurized furnace steam generators with all associated balance of plant equipment. Procurement activities were done directly by Bechtel/PGESCo through numerous material requisitions and purchase orders. The project procurement scope expanded to include traffic and logistics, marine cargo insurance, custom clearances, and in country freight. The project Owner was InterGen from the USA. The current Owner is PowerTech.

Plant Description

Sidi Krir 1&2 station consists of:

- Two indoor condensing steam turbine generator (STG) units, each capable of delivering 320 MW net power at the generator terminals.

- Two outdoor, dual firing, pressurized furnace steam generators.

- Auxiliary equipment including onsite oil storage, a natural gas pressure reducing and handling facility, a desalination plant for plant make-up water, an off-shore cooling water intake structure, a water and waste water treatment facility, a GIS 220 kV indoor switchyard, 220 kV transmission lines, and a housing colony.

Procurement activities for the project included the full scope of contract/purchase order formation and administration activities covering pre-qualification and evaluation of bidders, issuance of bid documents, bid evaluation, contract negotiations, contract award and expedition.

The project contracting plan used a multi-package system. Thirteen (13) contracting packages and seven (7) purchase orders were awarded to different contractors and suppliers to provide the station goods and services. The plant Owner awarded the different packages while PGESCo acted as the Owner authorized representative. The plant was turned over to the Owner and is in stable commercial operation since 2000.

Cairo West power project is designed to include one 650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500/220 KV GIS switchyard.

The power block is comprised of one Rankine cycle sub-critical turbine generator unit with a nominal rated capacity of 650 MW. The unit is capable of generating rated capacity using natural gas and/or heavy fuel oil (mazout). The unit arrangement includes an in-door turbine building, an out-door boiler structure, a control room, and all associated structures and facilities.

The project contracting plan utilized a multi-package system. Seventeen (17) contracting packages and purchase orders procured the equipment and services.

Plant Description

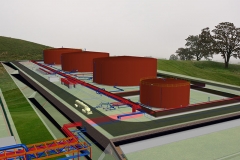

Assiut Supercritical Power Station site is located within the vicinity of Al Walidya Power Plant, in Assiut governorate,

- One indoor, condensing steam turbine generating unit,

- Rated 670 MW firing natural gas

- 650 MW firing Mazout (Max -VWO) at generator terminals.

- One outdoor, pressurized furnace steam generators duel fuel equipped with Dry Electrostatic Precipitator (DESP).

- Maximum Steam pressure 255 barg / Flow rate 581 Kg/Sec

- Necessary auxiliary equipment including:-

- Mazout fuel/ Solar storage tanks.

- Intake and discharge structures for plant cooling water.

- Water and Wastewater treatment,

- 500 kV GIS Switchyard facility.

Plant Description

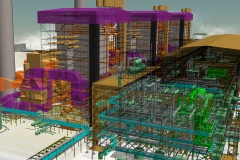

South Helwan power project is designed to include 3×650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500 KV GIS switchyard.

The power block is comprised of three identical Rankine cycle turbine generator units, each with a nominal rated capacity of 650 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both.

The three-unit plant arrangement includes an enclosed turbine building, an open boiler structure, a common control room, and all associated structures and facilities. The project contracting plan for the project utilizes the multi-package system. Seventeen (17) contracting packages and purchase orders procured the equipment and services

Plant Description

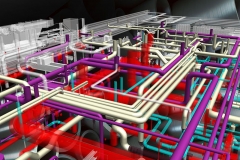

El Ain El Sokhna power project is designed to include a 2×650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a new 500 KV GIS switchyard. The power block is comprised of two identical Rankine cycle turbine generator units, each with a nominal rated capacity of 650 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both. The two-unit station arrangement includes an enclosed turbine building, an open boiler building, a common control room, and all associated structures and facilities.

The project contracting plan utilized a multi-package system. Eighteen (18) contracting packages and purchase orders procured the equipment and services.

The scope of work of the contract package of the 500kV single circuit for Cairo 500kV/Nubaria/Sidi Krir include Self supported lattice towers for single circuit in horizontal formation. The line is divided into two parts as follows:

Cairo-Nubaria 500 KV OHTL

Approximately 100 km route length of a single-circuit, three-bundles conductor, overhead transmission line from Cairo 500 kV substation to Nubaria Power Station.

An insulation level of 40 mm/kV was applied for this part of the line. 490/65 ACSR conductors (bundle of three per phase) were used for this part of the line. Galvanized steel shield wire of 108 mm2 cross sectional area was used as the first earth wire while OPGW are used as a second shield wire and communication purposes.

Sidi Krir-Nubaria 500 kV OHTL

Approximately 130 km route length of a single-circuit, three-bundle conductor, overhead transmission line from Sidi Krir 500 kV substation to Nubaria Power Station.

An insulation level of 40 mm/kV was applied for this part of the line, except for the last 30 km of the line (Sidi Krir direction) where 45 mm/kV insulation level was applied. 490/65 ACSR conductors (bundle of three per phase) was used for this part of the line, except for the last 30 km of the line (Sidi Krir direction), 506 mm2, AAAC (bundle of three per phase) was used. Galvanized steel shield wire of cross sectional area of 108 mm2 was used, except for the last 30 km of the line (Sidi Krir direction), 94.1 mm2 AACSR was used as the first earth wire while OPGW was used as a second shield wire and communication purposes for the whole line.

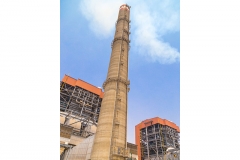

500 kV – Suez Canal Crossing Towers

Completed

Assist the Owner for specific activities such as;

- Evaluation of piling foundation

- Manage and schedule for the foundation and tower erection

South Helwan power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens are located. The water/waste water treatment installed in South Helwan power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Chlorine Gas feed system |

3 x 1300 kg cl2/h |

| Raw Water Pretreatment System |

Ultra filtration (UF) |

3 x 2400 m3/day |

| Demineralization System |

Reverse Osmosis + mixed bed demineralizer |

3 x 1200 m3/day |

| Condensate polisher System |

Externally Regenerated Mixed Beds |

3 x 900 m3/h |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

1920 m3/day |

| Potable water treatment |

UF + activated carbon filtration+ chlorination |

100 m3/day |

| Sewage treatment plant |

Extended aeration |

100 m3/day |

New Capital power project includes desalination and water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for HRSG feed as well as various power plant users. City water is supplied via pipe line to feed the water treatment system. The water/waste water treatment installed in New Capital power project includes:

| Pretreatment System |

Ultra filtration (UF) |

3 x 1800 m3/day |

| Desalination System |

reverse Osmosis (RO) system |

3 x 1200 m3/day |

| Demineralization System |

Electro Deionization |

3 x 960 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 480 m3/day |

| Sewage treatment plant |

Extended aeration STP |

2 x 100 m3/day |

Burullus power project includes desalination and water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for HRSG feed as well as various power plant users. Sea water from Mediterranean Sea is supplied via intake structure to feed the desalination system through power plant pump house where supply pumps and sea water screens is located. The desalination and water/waste water treatment installed in Burrulus power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

On-site Hypochlorite Generation |

3 x 40kg/hr Cl2 |

| Pretreatment System |

Ultra filtration (UF) |

3 x 2760 m3/day |

| Desalination System |

Double Pass reverse Osmosis (RO) system with energy recovery system |

3 x 1,000 m3/day |

| Demineralization System |

Electro deionization |

3 x 960 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 480 m3/day |

| Potable water treatment |

Activated carbon filters/remineralization filters |

2 x 100 m3/day |

| Sewage treatment plant |

Extended aeration STP |

2 x 100 m3/day |

Banha power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Banha power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification + Ultra filtration (UF) |

2280 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

3 x 1800 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2400 m3/day |

| Potable water treatment |

UF + Activated carbon filtration + chlorination |

100 m3/day |

| Sewage treatment plant |

Packaged Type – Extended aeration |

100 m3/day |

Giza North power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Giza North power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Chlorine Gas feed system |

3 x 1200 kg Cl2/h |

| Raw Water Pretreatment System |

Clarification + Ultra filtration (UF) |

3 x 2520 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

3 x 2040 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

5280 m3/day |

| Potable water treatment |

UF + activated carbon filtration+ chlorination |

80 m3/day |

| Sewage treatment plant |

Extended aeration |

80 m3/day |

Cairo West power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Cairo West power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration |

2 x 2400 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

2 x 1200 m3/day |

| Condensate polisher System |

Externally Regenerated Mixed Beds |

2 x 450 m3/h |

Sidi Krir power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Sea water from Mediterranean Sea is supplied via intake structure to feed the existing desalination plant and water/wastewater treatment system through power plant pump house where supply pumps and sea water screens are located. The desalination and water/waste water treatment installed in Sidi Krir power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

On site hypochlorite generation |

2 x 250 kg/hr |

| Demineralization System |

mixed bed deionizer |

2 x 1560 m3/day |

El Tebbin power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Al Tebbin power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration |

2 x 2400 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

2 x 1200 m3/day |

| Condensate polisher System |

Externally Regenerated Mixed Beds |

2 x 435.6 m3/h |

| Waste water treatment system |

Oil separation |

1 x 80 m3/h and 1 x 25 m3/h |

Kureimat power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The desalination and water/waste water treatment installed in El Kureimat power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration |

3 x 2400 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

3 x 1500 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

WW 2 x 1440 m3/day

Oil Sep 100 m3/h |

| Potable water treatment |

Activated carbon filtration+ chlorination |

20 m3/h |

Talkha power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. River water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Talkha power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtra-tion |

2 x 2800 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

2 x 2160 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 580 m3/day |

Nubaria power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. River water from Nubaria canal is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The desalination and water/waste water treatment installed in Nubaria power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration |

3 x 2016 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

3 x 1500 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 1440 m3/day |

| Potable water treatment |

Activated carbon filters and disinfection with sodium hypochlorite dosing |

400 m3/day |

| Sewage treatment plant |

Extended Diffused Aeration system |

2 × 200 m3/day |

Cairo North power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. River water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The water/waste water treatment installed in Cairo North power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration /Sludge Dewatering |

2 x 1680 m3/day |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

2 x 1680 m3/day |

| Waste water treatment system |

API Oil separation / DAF oil separation |

2400 m3/day |

Al Atf power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. River water from Nile River Rosetta Branch is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens is located. The desalination and water/waste water treatment installed in Al Atf power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Hypochlorite Solution injection system |

|

| Raw Water Pretreatment System |

Clarification / Multi Media Filtration |

2 x 80 m3/hr |

| Demineralization System |

Cation / degasifier /anion / mixed bed deionizer |

2 x 1300 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 840 m3/day |