Plant Description

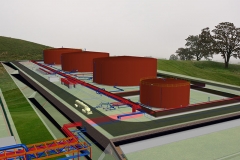

The West Damietta site is located on the Mediterranean Sea north coast, 15 km west of the New Damietta port near Damietta City. The existing facility consists of four (4) outdoor combustion turbine generators (CTGs) GE Frame 9E (4 x 125 MW) installed and commissioned in 2011. The new project accommodates one combined cycle module. It has a 4x4x1 configuration consisting of four (4) combustion turbines from the existing units. Each one feeds its exhaust gases to its respective heat recovery steam generator (HRSG), for a total of four (4) HRSGs and one 250 MW nominal steam turbine unit. Steam generated from the four (4) HRSGs feeds one 250 MW, non-reheat, condensing steam turbine generator (STG).

The new facility estimated 250 MW net output is achieved by burning natural gas in the CTGs with no supplementary firing in the HRSGs. The steam exhausted from the steam turbine is discharged into air cooled condenser. Air is used for the power plant cooling demand. Power generated is stepped up through a main transformer and fed to the utility grid via an onsite GIS existing switchyard facility 220 kV over head transmission line (OHTL). The current switchyard has space for one spare bay adequate for the new steam turbine unit.

The project contracting plan utilized a multi-package system. Eight (8) contracting packages and purchase orders procured the equipment and services.

Plant Description

Al Shabab site is located 33 Km West and 10 km South of Ismailia and El-Kassassin Cities respectively, in the Ismailia Governorate. The existing facility consists of eight (8) outdoor combustion turbine generators (CTGs) GE Frame 9E (8 x 125 MW) installed and commissioned in 2011.

The new project accommodates two (2) combined cycle modules. Both modules have a 4x4x1 configuration consisting of four (4) combustion turbines from the existing units. Each one feeds its exhaust gases to its respective heat recovery steam generator (HRSG) for a total of four (4) HRSGs and one 250 MW nominal steam turbine unit. Steam generated from the four (4) HRSGs feeds one 250 MW, non- reheat, condensing steam turbine generator (STG).

The new facility estimated 500 MW net output is achieved when burning natural gas in the CTGs with no supplementary firing in the HRSGs. The steam exhausted from the steam turbine is discharged into an air cooled condenser. Air is used for the power plant cooling demand. Power generated is stepped up through main transformers and fed to the utility grid via an onsite GIS existing switchyard facility 220 kV over head transmission line (OHTL). The current switchyard has space for two spare bays adequate for the new steam turbine units.

The project contracting plan utilized a multi-package system. Eight (8) contracting packages and purchase orders procured the equipment and services.

PGESCo scope included design review, site supervision and project management of Zwitina Combined Cycle 250 MW add-on Project. The scope also included plant material inspection and performance testing for all plant equipment. The scope is to convert the existing 2 X 250 MW Gas Turbine Power Plant into a 2X2X1 Combined Cycle Power Plant for a total capacity of 750 MW.

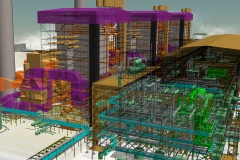

Cairo West power project is designed to include one 650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500/220 KV GIS switchyard.

The power block is comprised of one Rankine cycle sub-critical turbine generator unit with a nominal rated capacity of 650 MW. The unit is capable of generating rated capacity using natural gas and/or heavy fuel oil (mazout). The unit arrangement includes an in-door turbine building, an out-door boiler structure, a control room, and all associated structures and facilities.

The project contracting plan utilized a multi-package system. Seventeen (17) contracting packages and purchase orders procured the equipment and services.

Plant Description

Assiut Supercritical Power Station site is located within the vicinity of Al Walidya Power Plant, in Assiut governorate,

- One indoor, condensing steam turbine generating unit,

- Rated 670 MW firing natural gas

- 650 MW firing Mazout (Max -VWO) at generator terminals.

- One outdoor, pressurized furnace steam generators duel fuel equipped with Dry Electrostatic Precipitator (DESP).

- Maximum Steam pressure 255 barg / Flow rate 581 Kg/Sec

- Necessary auxiliary equipment including:-

- Mazout fuel/ Solar storage tanks.

- Intake and discharge structures for plant cooling water.

- Water and Wastewater treatment,

- 500 kV GIS Switchyard facility.

Plant Description

South Helwan power project is designed to include 3×650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500 KV GIS switchyard.

The power block is comprised of three identical Rankine cycle turbine generator units, each with a nominal rated capacity of 650 MW. The units are capable of generating rated capacity using natural gas, residual (mazout) oil, or a combination of both.

The three-unit plant arrangement includes an enclosed turbine building, an open boiler structure, a common control room, and all associated structures and facilities. The project contracting plan for the project utilizes the multi-package system. Seventeen (17) contracting packages and purchase orders procured the equipment and services

The following listed projects are under construction:

|

Substation |

Sub-contractor |

Year |

Equipment Type/Rating |

Configuration |

| 1 |

SOUTH HELWAN 500 kV |

Alstom Grid |

2015 |

500 kV GIS (Alstom Type T155), Busbar rating: 550 kV, 3150 A, 40 kA, 1sec, Breaker rating: 2000 A |

7 Bays, Double Busbar-Double Breaker |

| 2 |

AL SHABAB

220 kV switchyard Extension: |

Siemens |

2015 |

220 kV GIS (Siemens Type 8DN9), Busbar rat-ing: 245 kV, 2000 A, 50 kA, 1sec, Breaker rating: 1600 A |

Two Diameters, Breaker and a half |

| 3 |

WEST DAMIETTA 220 kV Switchyard Extension |

Hyundai |

2015 |

220 kV GIS (Hyundai Type 300 SR), Busbar rating: 245 kV, 2000 A, 50 kA, 1sec, Breaker rating: 2000 A |

One Diameter, Breaker and a half |

| 4 |

NEW ASSIUT

220 kV Switchyard Extension |

Siemens |

2016 |

220 kV GIS (Siemens Type 8DN9), Busbar rat-ing: 245 kV, 2000 A, 50 kA, 1sec, Breaker rating: 1600 A |

Two Diameters, Breaker and a half |

| 5 |

NEW WEST DAMI-ETTA

220 kV Switchyard Extension |

Alstom Grid |

2016 |

220 kV GIS (Alstom Type B105), Busbar rating: 245 kV, 2000 A, 50 kA, 1sec, Breaker rating: 1600 A |

One Diameter, Breaker and a half |

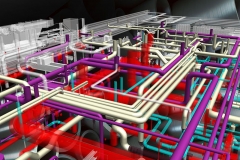

South Helwan power project includes water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for boiler feed as well as various power plant users. Raw water from Nile River is supplied via intake structure to feed the water treatment system through power plant pump house where supply pumps and raw water screens are located. The water/waste water treatment installed in South Helwan power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

Chlorine Gas feed system |

3 x 1300 kg cl2/h |

| Raw Water Pretreatment System |

Ultra filtration (UF) |

3 x 2400 m3/day |

| Demineralization System |

Reverse Osmosis + mixed bed demineralizer |

3 x 1200 m3/day |

| Condensate polisher System |

Externally Regenerated Mixed Beds |

3 x 900 m3/h |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

1920 m3/day |

| Potable water treatment |

UF + activated carbon filtration+ chlorination |

100 m3/day |

| Sewage treatment plant |

Extended aeration |

100 m3/day |

New Capital power project includes desalination and water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for HRSG feed as well as various power plant users. City water is supplied via pipe line to feed the water treatment system. The water/waste water treatment installed in New Capital power project includes:

| Pretreatment System |

Ultra filtration (UF) |

3 x 1800 m3/day |

| Desalination System |

reverse Osmosis (RO) system |

3 x 1200 m3/day |

| Demineralization System |

Electro Deionization |

3 x 960 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 480 m3/day |

| Sewage treatment plant |

Extended aeration STP |

2 x 100 m3/day |

Burullus power project includes desalination and water/waste water treatment systems to serve the plant water demand of high purity demineralized water required for HRSG feed as well as various power plant users. Sea water from Mediterranean Sea is supplied via intake structure to feed the desalination system through power plant pump house where supply pumps and sea water screens is located. The desalination and water/waste water treatment installed in Burrulus power project includes:

| Intake Design |

Open intake |

|

| Chlorination System |

On-site Hypochlorite Generation |

3 x 40kg/hr Cl2 |

| Pretreatment System |

Ultra filtration (UF) |

3 x 2760 m3/day |

| Desalination System |

Double Pass reverse Osmosis (RO) system with energy recovery system |

3 x 1,000 m3/day |

| Demineralization System |

Electro deionization |

3 x 960 m3/day |

| Waste water treatment system |

Oil separation / clarification / filtration / pH adjustment |

2 x 480 m3/day |

| Potable water treatment |

Activated carbon filters/remineralization filters |

2 x 100 m3/day |

| Sewage treatment plant |

Extended aeration STP |

2 x 100 m3/day |

PGESCo scope includes engineering, procurement and construction management services. The plant is owned to National Electricity Technology Co. “KAHRABA” is subsidiary of Egyptian Kuwait Holding Company licensed for producing and selling electricity.

The plant will include gas engine units rated for a total capacity of 60 MW and capable to continuously evacuate at part or full load in either grid or island mode.

The power will be generated at 11 kV, stepped up to 66 kV through two main oil transformers and evacuated through a new GIS substation within the property of the plant to the National Grid.