PGESCo engineering provides innovative solutions in various fields of power generation and industry including conceptual, detailed and final engineering design for civil, mechanical, electrical, control system and communication systems Services.

PGESCo executes detailed engineering plans from licensing to vendor interfacing.

Our skills include structural steel design, foundations design such as large rotating equipment foundations design, architectural design, electrical engineering design, equipment management and process design, Piping Stress analysis, layout, load analysis and piping supports design.

Engineering activities of conceptual, detailed or final design are covered by our highly experienced team

Architectural

Building Code Analysis

- Buildings occupancy classifications

- Means of emergency exits

- Life safety requirements

Full Range Architectural Design

- Project buildings

- Auxiliary facilities

- Ancillary facilities

Finishing Materials Specifications

- Multi-project standard specifications

- Project technical specifications

- Design criteria for architectural works

3D Modeling

Civil

Civil/Structural

- Dynamic analysis and design of machine foundation and complex structures.

- Analysis and design of:

- Steel structures/buildings.

- Reinforced concrete structures and foundation (shallow and deep foundation).

- Preparation of technical specifications, tender documents, evaluation of bidders, and recommendation of civil related award contracts.

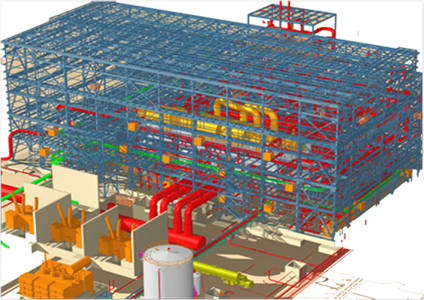

- 3D modeling of civil-commodities; including steel structures, concrete buildings, rebar detailing and underground circulating water pipping.

- Storm drainage and roads design.

Geotechnical

- Onshore/offshore soil investigation and geophysics.

- Geotechnical analysis and design.

- Seismic hazard assessment and analysis.

- Topographic survey and underground detection.

Hydraulic Works

- Hydrographic survey, hydraulic modelling.

- Design of circulating water system (onshore/offshore).

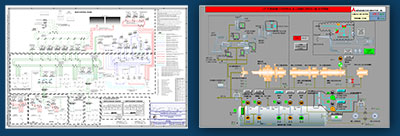

Control Systems

Automation and Control Design

- Distributed control system (dcs) specification

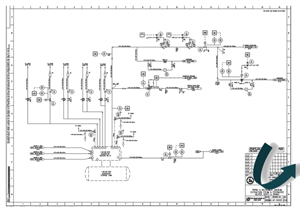

- Control systems architectural drawing

- Dcs sizing and I/o assignment

- Logic diagrams (plant protection, function block, and digital logic)

- Set point index

- Factory acceptance test (fat)

Instrumentation and Analysis Design

- Instrument selection.

- Instrument data sheets

- Control valve data sheets

- Control valve sizing and selection

- Instrument location plans

- Instrument installation details (iid)

- Continuous emissions monitoring system (cems)

- Steam and water analysis system (swas)

Electrical

Single-line and Phasing Diagrams

Single-line and Phasing Diagrams

- Main plant electrical distribution system (single-line diagrams)

- Plant phasing diagrams

Plant Cabling

- Cable design that includes cable type and size selection using PGESCo proprietary software.

- Cable routing that includes cable pathway selection, cable filling and length calculations, and cable pulling cards using both PGESCo proprietary and international software.

- Cable termination that includes cable termination cards.

- Cable MTOs and material tracking that includes cable quantities estimation and MTOs, cable installation follow-up and material tracking.

Metering and Relaying Single and Three-Line Diagrams

- Plant metering and relaying single-line diagrams

- Plant protection three-line diagrams

Equipment Modeling, Layout Drawings and Raceway System Design

- Equipment layout drawings

- Raceway system design

Breaker Logic Diagrams Power System Studies

- Short circuit calculations

- Load flow

- Motor start simulations

Electrical Equipment Sizing and Specification

Sizing and Specification for the Following:MV and LV Switchgear, Plant Power and LV Transformers, DC and UPS Equipment, Grounding System, Switchyard Equipment and Systems, Generator Circuit Breaker, and Isolated Phase Bus Duct

Protection Setting and Relay Coordination Study

Engineering Quality Assurance and Quality Control

Quality Assurance:

- Engineering procedures and instructions “EDPs, SEIs, GEIs and WPDs”

- Codes and standards

- Standard technical specifications

- Continuous training and development of engineers

- Audits planning “internal and external”

- Risk analysis and assessment

- Documents and records numbering system

- Codes and standards

- Lessons learned

Quality Control:

- Design checklists

- Documents and drawings register

- Calculation register

- 3D model review meeting

- Design checkers

- Design review notice “DRNs”

- Coordination forms

- Standard drawings

- Standard forms

- Risk register

- Progress reports

- Engineering performance measurement and scorecard

Environmental

- Technical specifications

- Reviewing project environmental impact assessment

- Coordinating and managing environmental activities between lending agencies such as the World Bank, African Development Bank and client

- Developing and maintaining environmental monitoring and due diligence programs for air, surface and groundwater, noise, traffic, soil and social conditions

- Writing environmental reports

- Ensuring project compliance with environmental regulations

Mechanical

- Power plant heat and mass balance conceptual design

- Preliminary design report

- Process piping and instrument diagrams P&IDs

- Pipe list, valve list, equipment list and specialty list

- Detail systems design calculation including piping and mechanical equipment sizing

- Equipment technical specifications

- Bidders technical evaluation

- Fired heat transfer equipment (Boiler/HRSG)

- Unfired heat transfer equipment (deaerator/feed water, heaters/heat exchanger)

- Rotating equipment (compressors/pumps)

- Performance testing

- Firefighting/HVAC

- Water and waste water treatment

- Desalination plants

Plant Design

Piping and Valves:

- Issue piping material classes

- Prepare specifications and material requisitions for piping, valves, and other in-line components, e.g. expansion Joints, traps, strainers, etc.

- Prepare pipe fabrication and installation specifications

- Prepare pipe insulation specification

- Material selection for piping and valves

Stress Analysis:

- Perform computer stress analysis of piping systems including: weight, thermal, wind, seismic, time history (steam hammer),dynamic loadings, and provide support loads and locations to the pipe support group

- Perform transient analysis

Equipment and Pipe Layout Design:

- Site layout optimization

- 3D modeling of mechanical equipment and major plant commodities

- Design and routing of different plant piping systems

- 3D Modeling of piping, fittings, valves, special devices etc.

- Ownership of plant 3D model and exchange it with contractors models run model review and interference checking of PGESCo design and contractors commodities